Cutting

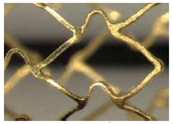

LASER CUTTING TECHNOLOGY: Cutting technology is independent of mechnical properties of materials in case usage of laser technology. Speed and quality of cutting are depend on optical properties of materials /refraction coefficient/. Laser cutting is the most popular laser technology and its sellings are the biggest on the laser market.

Main properties of laser cutting:

-

untouchable -

fast speed - high accuracy

-

narrow cutting gap -

low heat affect -

usually no burrs on the cutting surface -

energy saving technology

Every materials are able to machine with laser technology, comprehensive usage of many fields like different kinds of metals, plastics and is usable for glass , wood , paper parts too.

Applying of recent laser sources and moving units etc.:

25 mm-es structural steel 1 m/min,

15 mm-es stainless steel 0,7m/min,

15 mm-es AlMg3 sheet 1,2 m/min

In case of thin sheets /1mm/ cutting speed reaches 40 m/min,metal foils / like thickness is 0,1 mm, quality 1.4301/ cutting speed are 700 m/min. Wavelength of laser cutting is in infrared range /1070-, 10600 nm/, power of laser sources is between 100 -6000 W.

In case special materials can apply not in use lasers and optical ways. Special material or unusual producing environment may occur forming of individual cutting technology. Lasram able to create unique cutting technology, making sample parts and forming know-how of technology and its documentation.